Wheel service is one of the most repeatable, high-throughput areas of an automotive workshop, which also makes it one of the easiest places to lose time. A few small delays per job add up quickly across a day, and they usually show up as: longer queues, tech frustration, and missed revenue opportunities.

This guide covers practical ways to reduce turnaround time while keeping results consistent and safe.

For a broader overview of workshop category planning, start here: workshop equipment guide.

Where wheel service time is usually lost

Most “slow wheel service” isn’t caused by one big issue — it’s a stack of small ones.

Common bottlenecks include:

Vehicles waiting for a bay or hoist

Tyres waiting to be changed because the changer/balancer is tied up

Rework caused by poor balance results or inconsistent processes

Techs walking back and forth for weights, valves, tools, and consumables

Slow setup time for different wheel types (low-profile, run-flats, larger SUVs, etc.)

If you want to sanity-check whether it’s equipment or workflow, track one simple number for a week:

average minutes per wheel set (vehicle arrives at wheel bay → wheels balanced, refitted, and final-torqued)

Quick wins that improve throughput (without buying anything)

Before you upgrade equipment, these process tweaks often deliver immediate results.

1) Set up a dedicated wheel service zone

Keep everything within arm’s reach:

Weights, valves, consumables

Torque wrench + sockets

Cleaning supplies

Tyre lube, tools, accessories

The goal is to remove “micro-walks” and interruptions.

2) Standardise your wheel service checklist

A short, repeatable checklist reduces rework. For example:

Inspect tyre and rim condition

Set correct pressure targets

Balance process and weight placement consistency

Torque procedure and final check

3) Batch where it makes sense

If your workshop flow allows it, batching similar jobs can reduce changeover time (especially if you handle lots of similar wheel sizes).

When equipment is the limiter (and what to prioritise)

If the same machine is “the queue” every day, it’s worth checking whether your equipment is matched to your vehicle mix and volume.

Ask:

Are we mostly passenger vehicles, or lots of SUV/utes?

Do we regularly see low-profile or difficult tyre types?

What’s our busiest day volume?

Are we doing more tyre work seasonally?

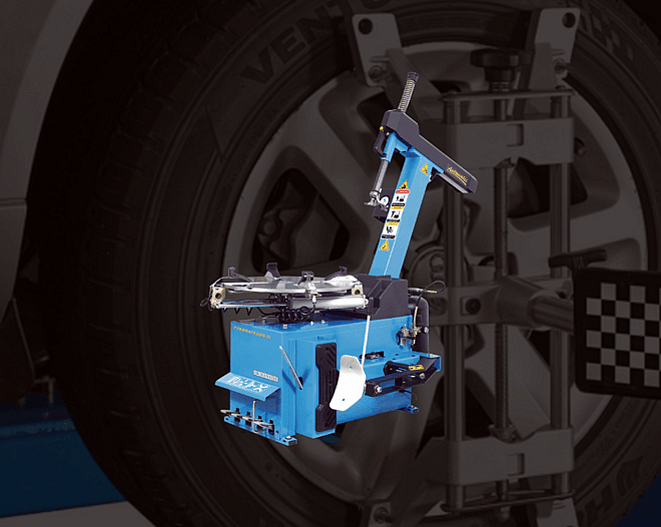

Explore category options here: wheel service equipment →

Signs it’s time to upgrade

Consistent delays even when techs are ready to work

Repeated re-balancing / vibration comebacks

Difficulty handling modern wheel/tyre profiles

The machine is the bottleneck (not bay availability)

Don’t treat wheel service and alignment as separate silos

Many workshops lose time because the wheel service process isn’t aligned with the alignment process (or vice versa). A smooth “wheel service → alignment → final check” workflow can remove a lot of downtime.

If alignment is part of your service offering, ensure workflow planning includes both:

Simple KPIs to track (so you know what to fix)

You don’t need complex reporting — just a few measures:

Average turnaround time per wheel set (minutes)

Rework rate (how often a job returns for vibration/balance issues)

Peak time queue length (how many vehicles waiting at busiest period)

Technician “idle time” caused by waiting for a machine or bay

Even basic tracking helps you identify whether the constraint is people, process, bays, or equipment.

Quick checklist to reduce wheel service turnaround time

Use this as a practical audit:

Is wheel service set up as a dedicated zone with all consumables on hand?

Do we have a consistent checklist and torque process?

Are the machines matched to our wheel/tyre mix (SUV/utes/low-profile/run-flat)?

Are we seeing rework or vibration comebacks?

Is the workflow smooth between wheel service and alignment (if applicable)?

Are we tracking time per job so we know what’s actually slowing us down?

If you can’t confidently answer these yet, it’s worth mapping your wheel service workflow before investing in new equipment.

If wheel service is a bottleneck in your workshop, improving throughput is one of the quickest ways to lift daily capacity.

Not sure what to prioritise?

Tell us your vehicle mix and expected volume, and we’ll recommend wheel service equipment that fits your workflow and throughput goals.